About us

Paul’s Fan Company got its start by providing essential, rugged ventilation equipment that improved safety and efficiency for members of the mining industry across the country. As the economy has changed, Paul’s Fan Company has adjusted its business model. The company has expanded into a wide variety of industries. In addition to mining, it now fabricates fans for steel, fiber, pharmaceutical and chemical companies.

In addition to building and installing brand new ventilation systems, Paul’s Fan Company has had the capacity for complex rebuilds since its very beginnings. Paul’s Fan Company has managed fan rebuilds for more than six decades.

Currently, a renewed focus on sustainability, from an environmental, political, and economic perspective, has made rebuilds an even more attractive option to industry leaders.

Paul’s Fan Company’s skilled fan technicians install, balance, and maintain rotating parts on a rebuilt rotating assembly.

HOW IT WORKS

“Rebuilding” industrial fans involves taking component parts that were previously used, remaking them, conditioning them, and putting those parts back into service. Recently, Paul’s Fan Company rebuilt a fan from an abandoned mine shaft.

The Paul’s Fan Company team starts by removing every rotating part from the fan, then extracting the shaft and motor. The team replaces worn out pulleys, changes bearings, cleans the shaft and blade, installs all new firings and then reassembles the fan.

Throughout the process, the fan is blasted and entirely repainted. The fan looks just like new, and Paul’s Fan Company ensures that it functions like-new, too. After final assembly, the fan is thoroughly tested by technicians and pre-balanced with the shop’s in-house balance machine. The fan will be ready to run on delivery.

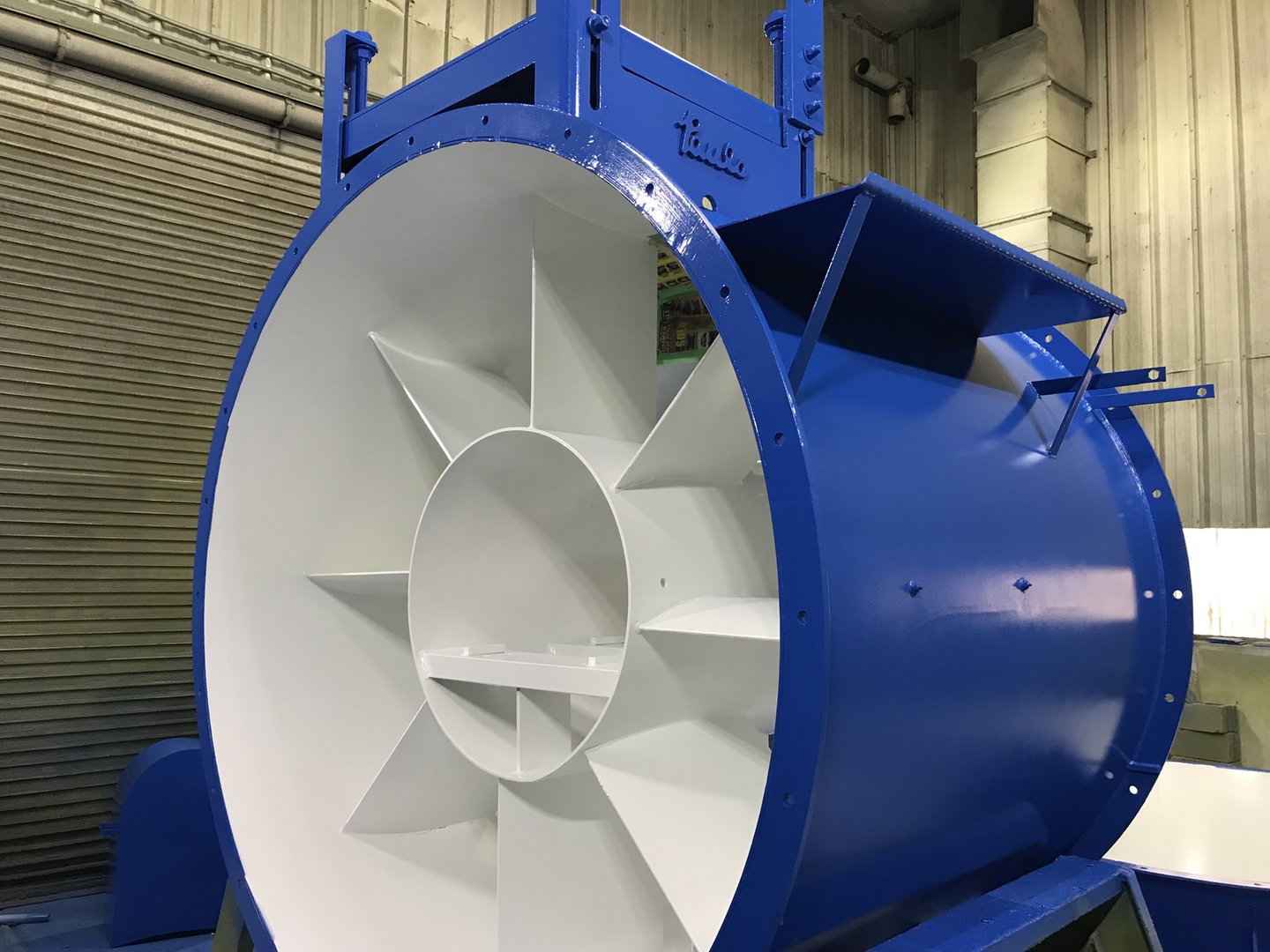

Rebuilt fan housing

A CHANGING ECONOMY

A changing economy can lead to uncertainty, which can significantly influence a company’s capital spending and long-term goals. Rebuilds have been in high demand recently, as cash-strapped companies have faced the necessity of fixing current equipment rather than replacing it.

The good news is, Paul’s Fan Company has more in-stock replacement parts for fans and industrial equipment than most companies in the United States. Their team can help you stay operational and adhere to your budget.

SAVE TIME & MONEY

Opting for a rebuilt fan won’t only save you money—it will also save you time. Rebuilds can take months off a tight production schedule and help you stick to your own project timeline, without scrimping on quality.

Brand new fans can have a 12-month or more lead time. Rebuilt fans can shave several months off that turnaround time. You’ll still be able to rely on Paul’s Fan Company products for the life of your business. Most rebuilt fans are also eligible for warranties.

THE SUSTAINABLE CHOICE

As industry and regulation is changing, more mining and industrial companies are establishing measures to partner with and/or purchase from suppliers that mirror their corporate environmental policies. Choosing rebuilt fans over new manufacturing is a sustainable choice to consider. Paul’s Fan Company can use up to 50% recycled or reused components in a rebuilt fan, which means customers can save on material cost while also decreasing their environmental impact.

Ultimately, a rebuilt fan may be an even better fit for an industrial space than a manufactured one. Paul’s Fan Company has the inventory of parts, technical skill and mechanical capacity to repurpose an existing fan and make it work for a specific client.

This means that companies who use Paul’s Fan products won’t have to adjust their workflows to suit the equipment they use. For example, Paul’s Fan Company can provide solutions that may improve efficiency and output with the customer’s current systems and workflow in place.

Paul’s Fan Company’s Remanufactured Services include:

- Complete Rebuilds for axial, centrifugal and portable fans

- Blade Assembly rebuilds

- Tipping and De-Tipping blades

- Fan Retrofits for nearly all manufacturers

- Tier 4 Engine Retrofits for fans in production

- Custom Ductwork design and manufacturing

- Non-Return Doors and airlock chambers

- Electrical houses and automation products

- Turn Key Installation

contact us

Contact Paul’s Fan Company today and let us design a safe and efficient ventilation system that’s custom-built to meet your needs.

Ventilation Systems for Mining & Large Industrial Applications

Paul’s Fan Company was founded by Paul Elswick in 1958. Today, we manufacture, install, service, and repair large and complex ventilation systems. We have built more than 5,000 industrial blowers and fans across the U.S., Canada, and Mexico for a variety of industries ranging from mining to large commercial buildings and factories.

We’d love to discuss your industrial fan installation needs. Contact us to today!

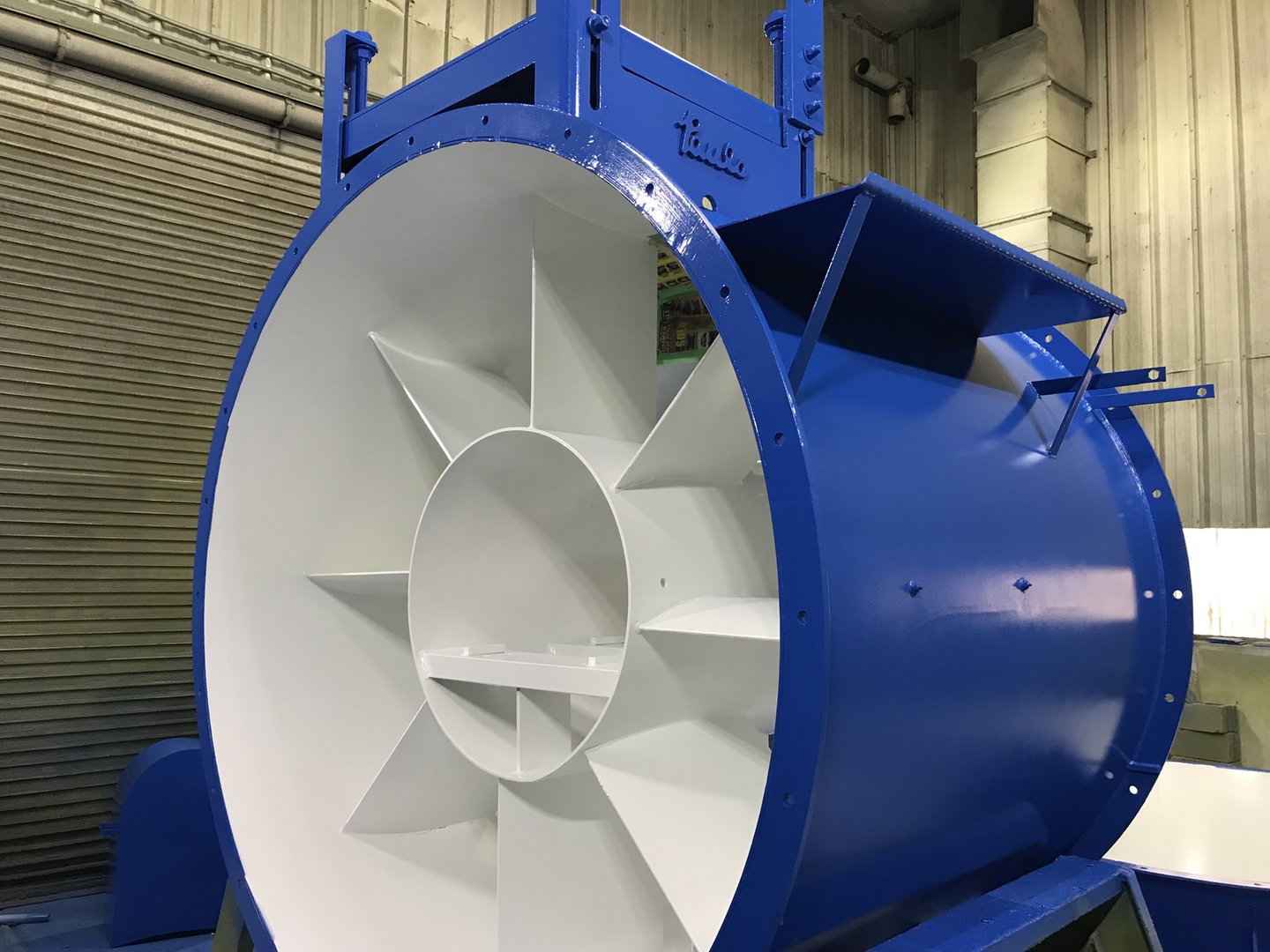

Lowering a rebuilt retrofit fan unit into existing fan in production.

Ventilation Systems for Mining & Large Industrial Applications

About us

Paul’s Fan Company got its start by providing essential, rugged ventilation equipment that improved safety and efficiency for members of the mining industry across the country. As the economy has changed, Paul’s Fan Company has adjusted its business model. The company has expanded into a wide variety of industries. In addition to mining, it now fabricates fans for steel, fiber, pharmaceutical and chemical companies.

In addition to building and installing brand new ventilation systems, Paul’s Fan Company has had the capacity for complex rebuilds since its very beginnings. Paul’s Fan Company has managed fan rebuilds for more than six decades.

Currently, a renewed focus on sustainability, from an environmental, political, and economic perspective, has made rebuilds an even more attractive option to industry leaders.

Paul’s Fan Company’s skilled fan technicians install, balance, and maintain rotating parts on a rebuilt rotating assembly.

HOW IT WORKS

“Rebuilding” industrial fans involves taking component parts that were previously used, remaking them, conditioning them, and putting those parts back into service. Recently, Paul’s Fan Company rebuilt a fan from an abandoned mine shaft.

The Paul’s Fan Company team starts by removing every rotating part from the fan, then extracting the shaft and motor. The team replaces worn out pulleys, changes bearings, cleans the shaft and blade, installs all new firings and then reassembles the fan.

Throughout the process, the fan is blasted and entirely repainted. The fan looks just like new, and Paul’s Fan Company ensures that it functions like-new, too. After final assembly, the fan is thoroughly tested by technicians and pre-balanced with the shop’s in-house balance machine. The fan will be ready to run on delivery.

Rebuilt fan housing

A CHANGING ECONOMY

A changing economy can lead to uncertainty, which can significantly influence a company’s capital spending and long-term goals. Rebuilds have been in high demand recently, as cash-strapped companies have faced the necessity of fixing current equipment rather than replacing it.

The good news is, Paul’s Fan Company has more in-stock replacement parts for fans and industrial equipment than most companies in the United States. Their team can help you stay operational and adhere to your budget.

SAVE TIME & MONEY

Opting for a rebuilt fan won’t only save you money—it will also save you time. Rebuilds can take months off a tight production schedule and help you stick to your own project timeline, without scrimping on quality.

Brand new fans can have a 12-month or more lead time. Rebuilt fans can shave several months off that turnaround time. You’ll still be able to rely on Paul’s Fan Company products for the life of your business. Most rebuilt fans are also eligible for warranties.

THE SUSTAINABLE CHOICE

As industry and regulation is changing, more mining and industrial companies are establishing measures to partner with and/or purchase from suppliers that mirror their corporate environmental policies. Choosing rebuilt fans over new manufacturing is a sustainable choice to consider. Paul’s Fan Company can use up to 50% recycled or reused components in a rebuilt fan, which means customers can save on material cost while also decreasing their environmental impact.

Ultimately, a rebuilt fan may be an even better fit for an industrial space than a manufactured one. Paul’s Fan Company has the inventory of parts, technical skill and mechanical capacity to repurpose an existing fan and make it work for a specific client.

This means that companies who use Paul’s Fan products won’t have to adjust their workflows to suit the equipment they use. For example, Paul’s Fan Company can provide solutions that may improve efficiency and output with the customer’s current systems and workflow in place.

Paul’s Fan Company’s Remanufactured Services include:

- Complete Rebuilds for axial, centrifugal and portable fans

- Blade Assembly rebuilds

- Tipping and De-Tipping blades

- Fan Retrofits for nearly all manufacturers

- Tier 4 Engine Retrofits for fans in production

- Custom Ductwork design and manufacturing

- Non-Return Doors and airlock chambers

- Electrical houses and automation products

- Turn Key Installation

contact us

Contact Paul’s Fan Company today and let us design a safe and efficient ventilation system that’s custom-built to meet your needs.

Ventilation Systems for Mining & Large Industrial Applications

Paul’s Fan Company was founded by Paul Elswick in 1958. Today, we manufacture, install, service, and repair large and complex ventilation systems. We have built more than 5,000 industrial blowers and fans across the U.S., Canada, and Mexico for a variety of industries ranging from mining to large commercial buildings and factories.

We’d love to discuss your industrial fan installation needs. Contact us to today!

Lowering a rebuilt retrofit fan unit into existing fan in production.