Choosing the right slurry pump is like choosing the best tool for the job. It takes a bit of research of the product and knowing your application. In doing this you will be able to determine the best performing pump for your operation with the best total cost of ownership.

To begin the pump selection process, there are four pieces of information that are required to get a basic pump size and calculate motor power:

- Flow Rate

- Head (pipeline information)

- Specific gravity of slurry

- Particle size

If you don't have this information on hand, start with the condition and application.

Scroll down to find out which pump works best for your operation.

Have questions or want to learn more about the steps to choosing the right slurry pump? Download this helpful presentation.

KSB GIW, Inc. www.ksb.com/en-us

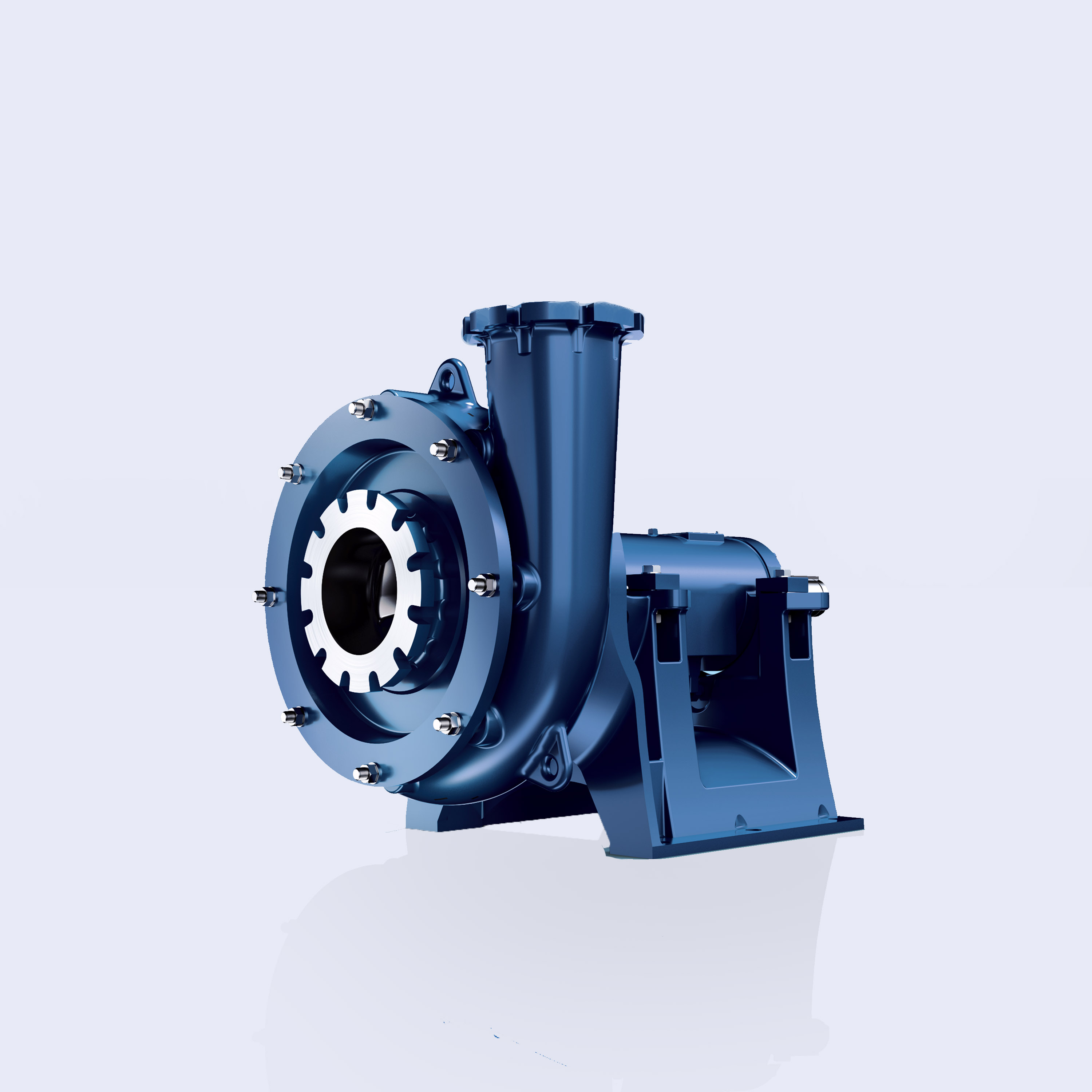

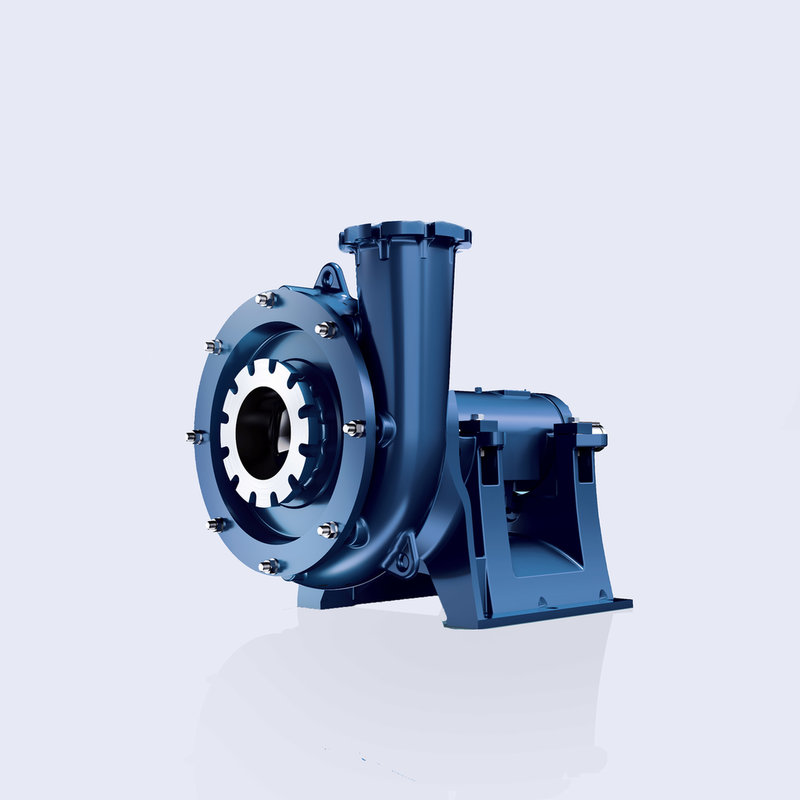

Class 1-3 Slurry

Applications: sand and gravel, in-plant processes, mineral processing, secondary grinding, tailings, chemical slurry service, and coal preparation.

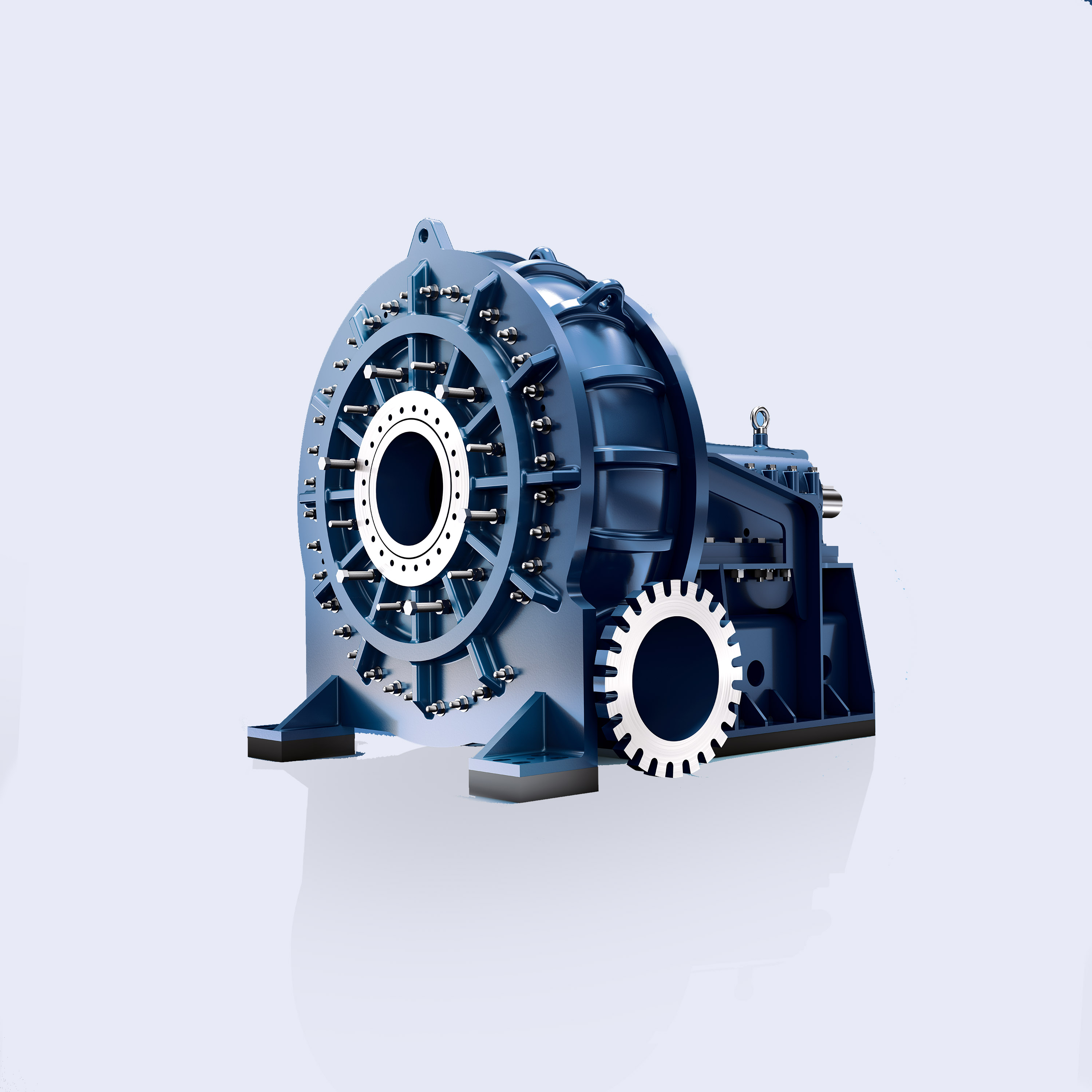

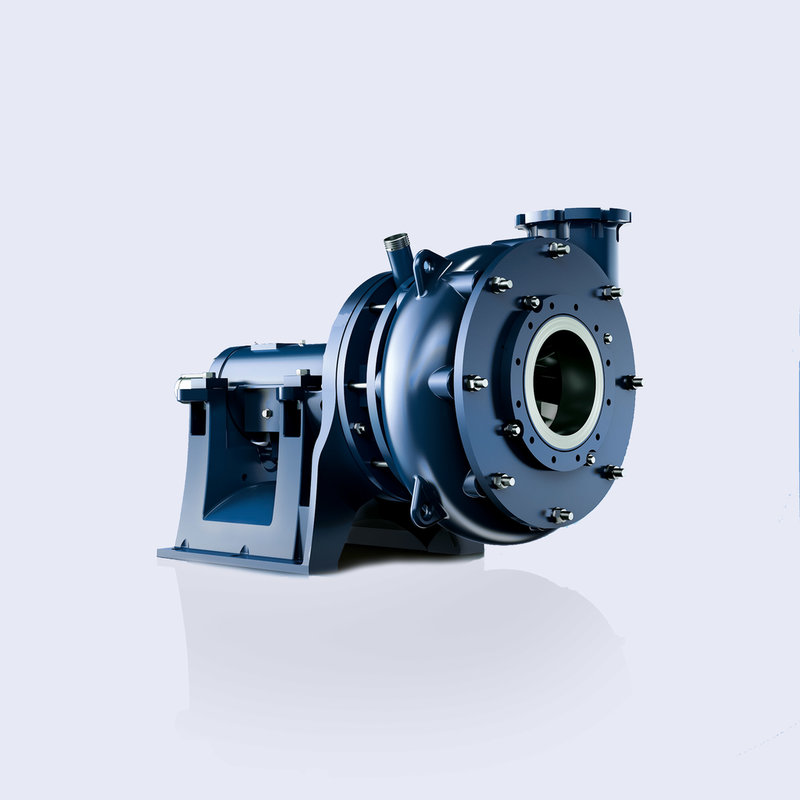

Class 4 Slurry

Applications: mineral processing, power generation, aggregate, ash handling, flue gas desulfurization, thickener & tailings, mine dewatering, industrial slurries, and dredge.

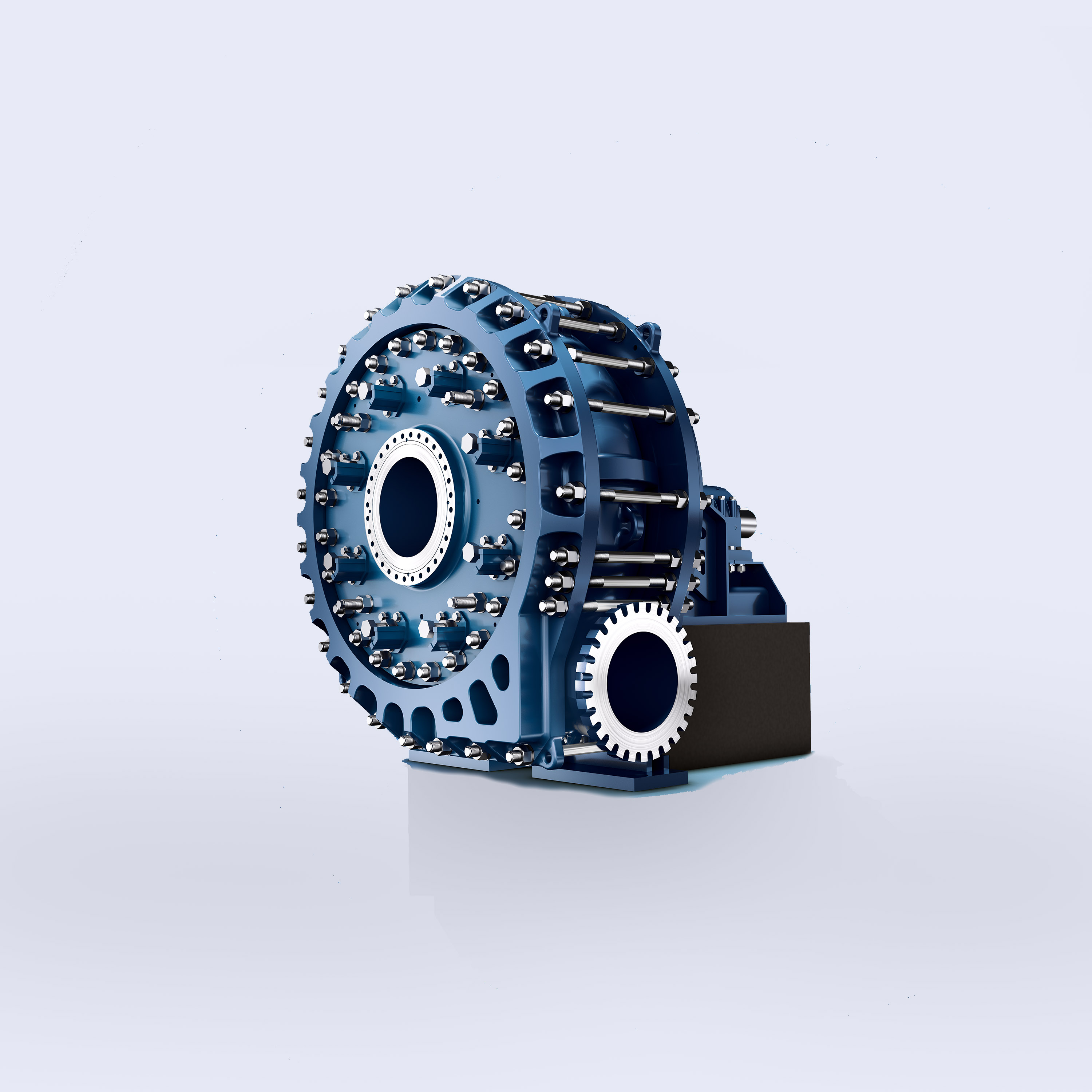

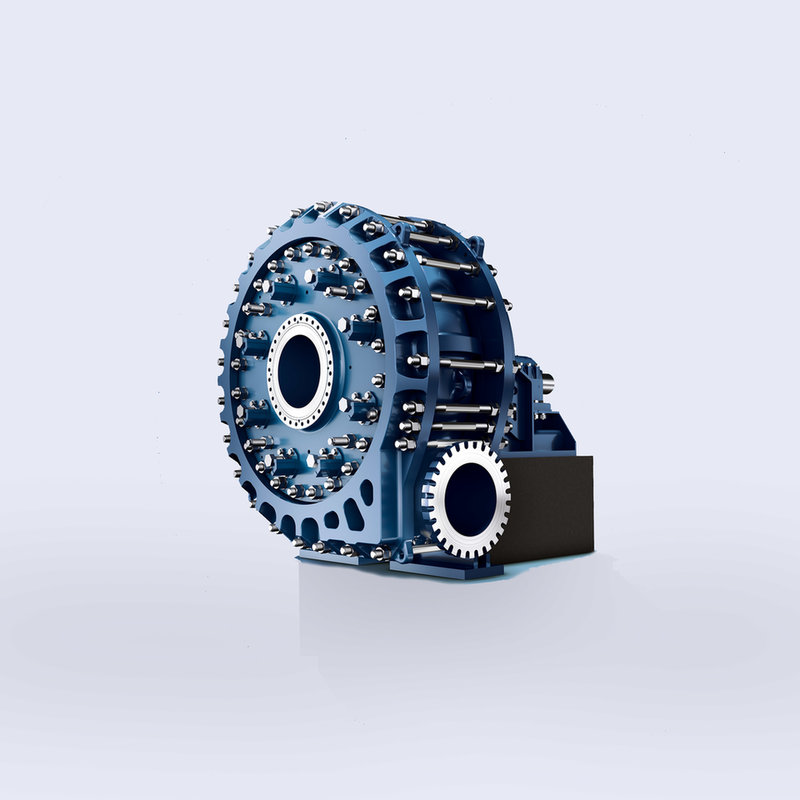

Class 3-4 Slurry

Applications: SAG, ball and rod mill discharge, and cyclone and screen feed.

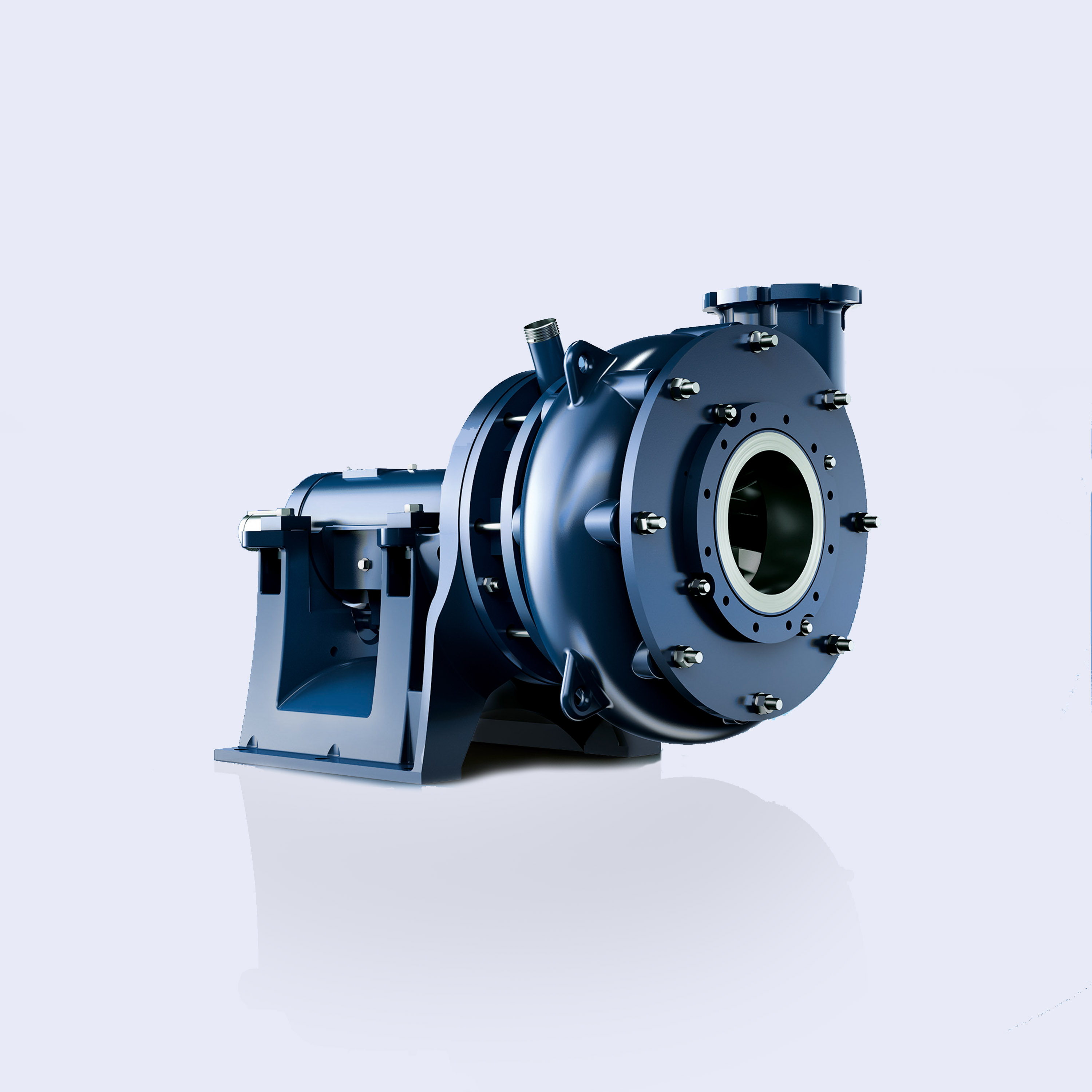

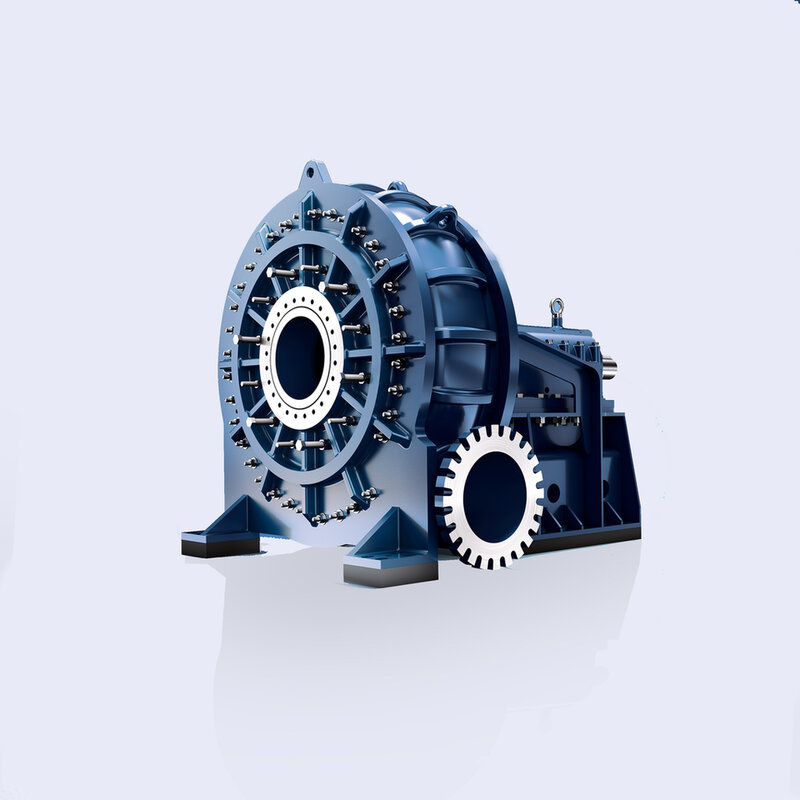

Class 3-4 Slurry

Application: severe duties, oil sands, hydraulic transport, ore and mineral tailings, and pipeline booster stations.

Class 1-2 Slurry

Applications: oil sands, hard rock mining, and mineral and froth processes.

Class 4 Slurry

Applications: Phosphate, Tailings, Ore Slurries, Hydraulic Transport, Pipeline Booster Stations

Class 1-2 Slurry

Applications: Tailings Pond Dewatering, Water Reclamation (Oil Sands Fluid Fine Tails, Thin Fine Tails, Mature Fine Tails)