Company Insight

Sponsored by Vayeron

How Vayeron's Smart-Idler® is setting new standards in conveyor monitoring

Standfirst...

Main image credit:

Vayeron specialises in conceptualising, designing, and manufacturing IoT products tailored to the bulk material handling sector.

Since its inception in 2015, Vayeron has been at the forefront of revolutionising the bulk material handling industry. Emerging from a small start-up, the company has grown into a recognised innovator and thought leader, driven by a commitment to simplifying complex problems through advanced technological solutions.

The company's solutions are crafted to maximise operational efficiencies by collecting valuable data that predicts and prevents potential issues. This proactive approach to maintenance ensures that businesses can operate smoothly, reducing downtime and minimising operational costs.

Caption. Credit:

Vayeron Smart-Idler®: Never worry about your idlers again

50% of bulk material unscheduled conveyor downtimes are due to roller failure, and downtime opportunity costs of $100k-500k+ per hour are common. Vayeron's Smart-Idler® addresses this issue by providing real-time, autonomous monitoring of conveyor roller conditions, predicting and detecting failure modes such as bearing failure and shell wear.

What would a catastrophic failure cost your company?

Bulk material conveyors move an estimated $3T material per annum. The opportunity cost of conveyor roller failure is approximately $20B+ p.a.

The Smart-Idler® was inspired by a real-life incident experienced by Vayeron's founder, Ryan, who witnessed the catastrophic failure of a $20 million conveyor belt due to roller failure.

- The belt, with a 10-year life expectancy, had to be replaced in just four years.

- It was placed on life support for two months, massively increasing maintenance costs.

- Many mining companies treat these situations as a cost of doing business.

- High roller quantities often mean a lack of thorough maintenance and life cycle visibility, made worse by inadequate manual inspection.

- Critical conveyors or zones are changed in batches, meaning each zone is shut down 1+ times per year.

This incident highlighted the need for a more reliable and proactive monitoring system. The Smart-Idler® not only prevents such costly failures but also reduces the need for frequent manual inspections, making it a valuable asset for any bulk material handling operation.

Failed rollers can cause catastrophic fires

Many notable fire incidents in the mining industry have been made very public. From these cases, the likelihood and financial impact of a catastrophic fire incident can be calculated.

For instance, a $20M incident, which is approximately a 1-in-50-year event, would have an annualised cost of $400,000. This cost is an annual consideration for insurance premiums.

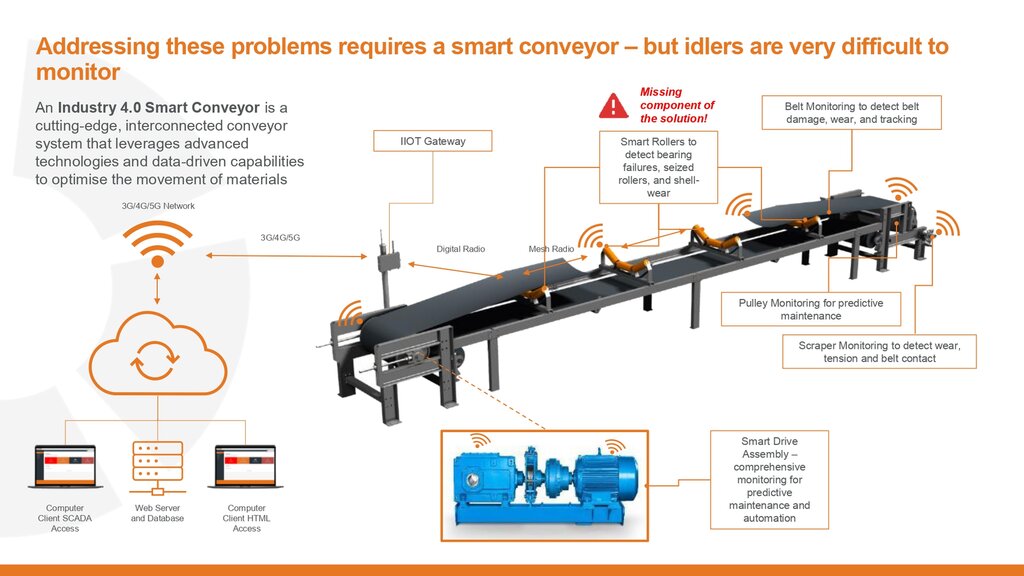

Conveyors are getting smarter to address the above problems

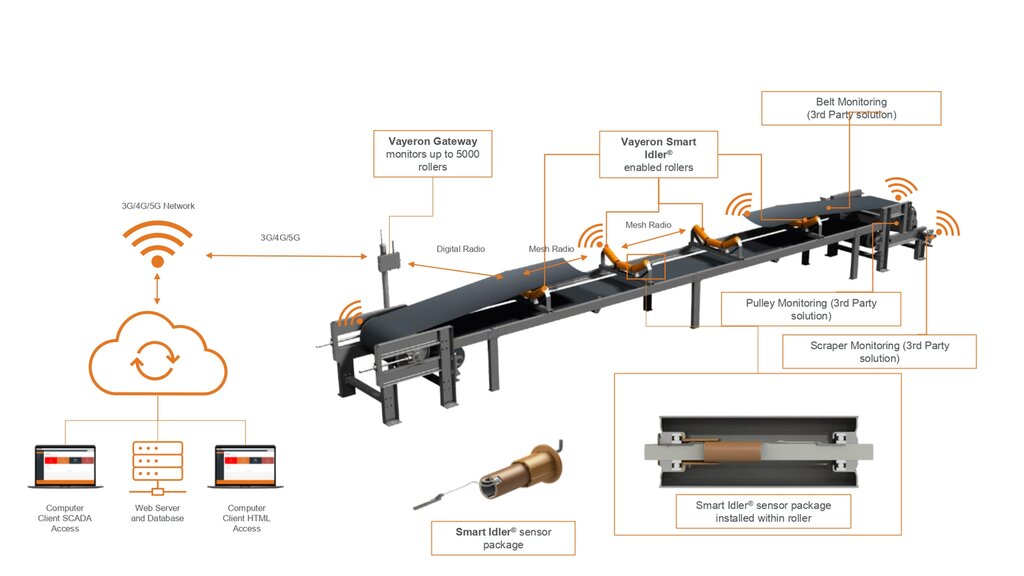

Vayeron Smart-Idler® Data is streamed directly from your conveyor to your fingertips.

Vayeron Smart Idler® is the only solution proven at scale for condition monitoring of rollers in a Smart Conveyor application.

The Smart-Idler® is equipped with various advanced features

The Smart-Idler® is self-powering, making it easier and cheaper to install and maintain. It is also easily integrated by existing manufacturers. Roller Failure Prediction allows scheduled maintenance, increased conveyor uptime, and overall improved awareness of conveyor performance.

The Smart-Idler® measures:

- RPM

- Vibration

- Temperature

And provides analytics for:

- Shell wear

- Carryback buildup

- Frame misalignment

- Bearing defects

- Loose structure

- Overheating

Serving the titans of industry

Vayeron's clientele includes tier-one mining companies and bulk handling sector suppliers. By working closely with roller and conveyor manufacturers, Vayeron integrates its products into existing systems, providing a future-proof solution that enhances plant and equipment performance. The company’s technologies simplify operational data sources for business-critical machinery, enabling clients to achieve greater efficiency and reduce condition monitoring costs.

The company's innovative technologies are setting industry standards and can be found in industrial operations across four continents.

Experience the Smart-Idler® at MINExpo 2024!

Vayeron will be showcasing its groundbreaking Smart-Idler® technology at MINExpo 2024 in Las Vegas from September 24-26. This event will provide an opportunity for industry leaders to witness firsthand how Vayeron's solutions are shaping the future of bulk material handling.

Contact information

Vayeron

L2, Building 4, 92 Sydney St CQ University,

Mackay, QLD, Australia

Tel.: +61 1800 404 160

Email: info@vayeron.com.au

Web: www.vayeron.com