Protection from head to tail

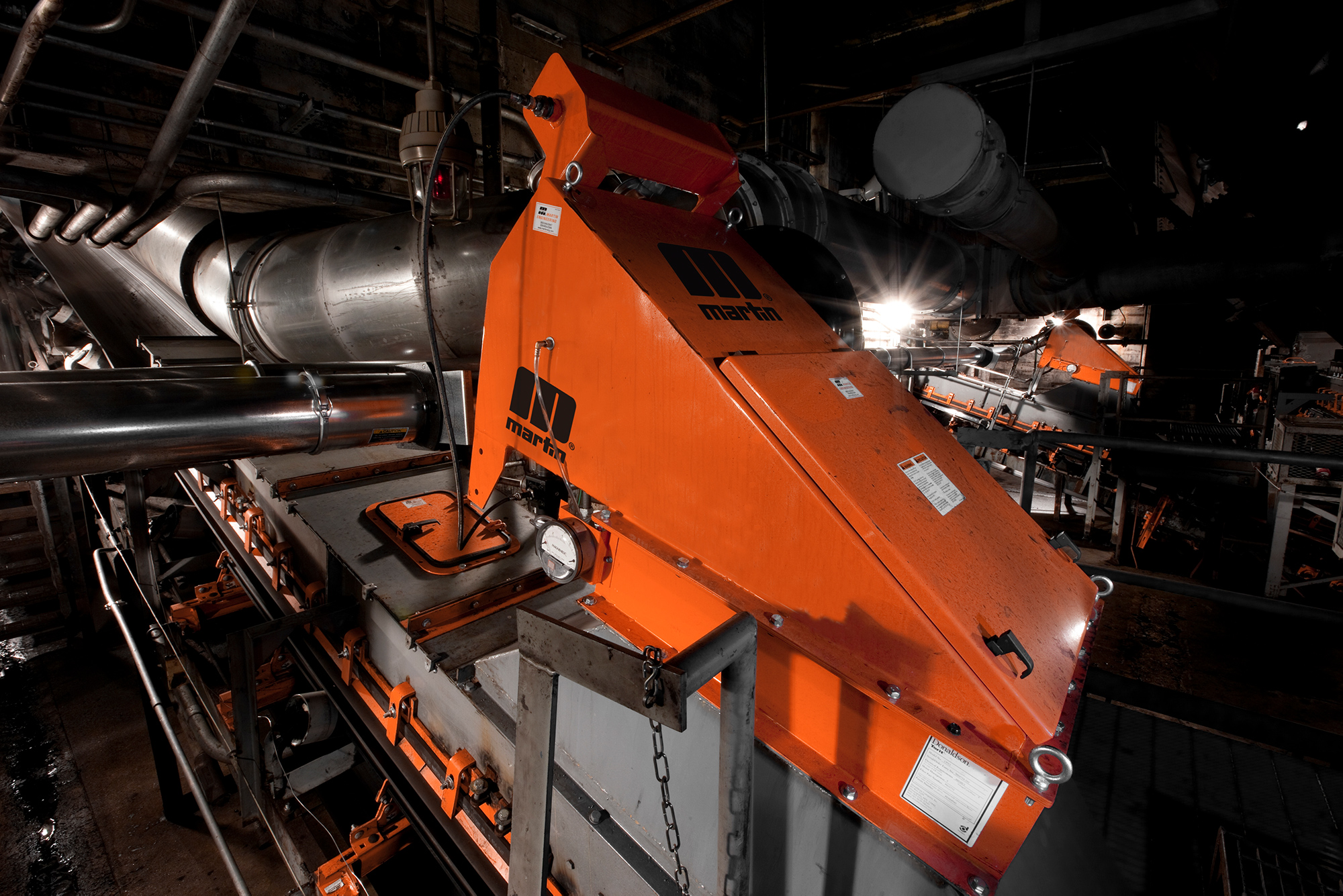

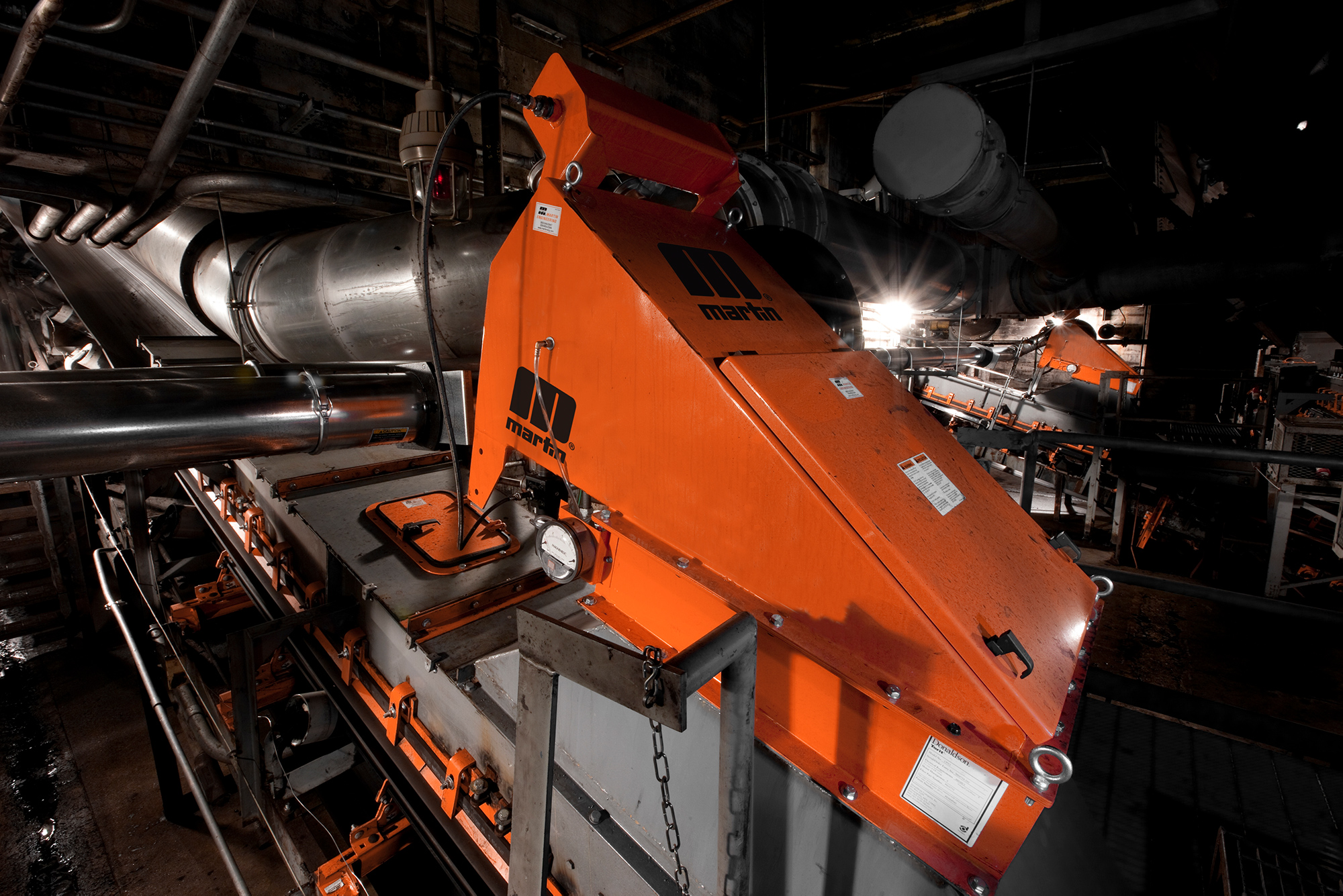

Whether you’re mining coal, precious metals, base metals or aggregates, you can rely on the fact that Martin Engineering has been a leader in the original development of the conveyor belt equipment used today to make mining operations cleaner, safer and more productive.

We employ many people who have worked extensively in the mining industry, so we’re able to apply lessons learned from all over the world to solving your everyday problems, from underground to surface mining operations. We take the time to understand the specifics of your plant, which allows us to provide the correct equipment for your application and point out areas where you can be even more efficient and profitable. At Martin, we contribute to the availability and reliability of your transport system, implementing equipment and solutions that guarantee a clean, safe, and effective bulk handling process.

We develop solutions that maintain the durability of your conveyor components from head to tail. Creating an efficient system of bulk material handling with safety, profitability, and technology, providing availability for your system.

Check out our solutions for mining operations

Belt Cleaning

High-performing belt cleaners keep belts clean, eliminating carryback and making conveyor systems safer and more productive. Our belt cleaners that work with all belt sizes and speeds, regardless of industry or type of material. We also offer belt cleaners that work in the most challenging and unique environments, such as on conveyor systems where there’s minimal space around the head pulley.

Transfer Point

We are a worldwide leader when it comes to making conveyors run better because we have experience that stretches back decades, working with many of the largest manufacturers in the world. Our transfer point products are designed to be effective over a long work life, even under the most demanding conditions. Which means, we keep conveyor systems precisely aligned and working perfectly.

Dust Management

At Martin Engineering, we take dust seriously! In addition to causing health issues when inhaled, it can ignite and explode under certain conditions. Our dust management solutions are the most effective in the business, offering filtration products that pull airborne dust out of the air and return it safely to the material stream and manufacturing equipment that contains dust at the source and provide solutions that suppress dust after it’s in the air.

Flow Aid

High-performing belt cleaners keep belts clean, eliminating carryback and making conveyor systems safer and more productive. Our belt cleaners that work with all belt sizes and speeds, regardless of industry or type of material. We also offer belt cleaners that work in the most challenging and unique environments, such as on conveyor systems where there’s minimal space around the head pulley.

With our experienced technicians, we’re able to offer an unmatched level of support and service to the facilities we visit. And many of our engineers and technicians have previously worked for mining companies like yours, so we have a unique perspective and advantage when it comes to knowing the issues you face from your viewpoint. We have decades of direct experience, and we know where the process can get bogged down. More importantly, we know how to fix the problems when they arise.

Contact a Martin representative to find out how we can apply our vast mining experience to solve your problems the right way.

Martin Engineering Australia

www.martin-eng.com.au

+61 1300 627 364

Protection from head to tail

Whether you’re mining coal, precious metals, base metals or aggregates, you can rely on the fact that Martin Engineering has been a leader in the original development of the conveyor belt equipment used today to make mining operations cleaner, safer and more productive.

We employ many people who have worked extensively in the mining industry, so we’re able to apply lessons learned from all over the world to solving your everyday problems, from underground to surface mining operations. We take the time to understand the specifics of your plant, which allows us to provide the correct equipment for your application and point out areas where you can be even more efficient and profitable. At Martin, we contribute to the availability and reliability of your transport system, implementing equipment and solutions that guarantee a clean, safe, and effective bulk handling process.

We develop solutions that maintain the durability of your conveyor components from head to tail. Creating an efficient system of bulk material handling with safety, profitability, and technology, providing availability for your system.

Check out our solutions for mining operations

Belt Cleaning

High-performing belt cleaners keep belts clean, eliminating carryback and making conveyor systems safer and more productive. Our belt cleaners that work with all belt sizes and speeds, regardless of industry or type of material. We also offer belt cleaners that work in the most challenging and unique environments, such as on conveyor systems where there’s minimal space around the head pulley.

Transfer Point

We are a worldwide leader when it comes to making conveyors run better because we have experience that stretches back decades, working with many of the largest manufacturers in the world. Our transfer point products are designed to be effective over a long work life, even under the most demanding conditions. Which means, we keep conveyor systems precisely aligned and working perfectly.

Dust Management

At Martin Engineering, we take dust seriously! In addition to causing health issues when inhaled, it can ignite and explode under certain conditions. Our dust management solutions are the most effective in the business, offering filtration products that pull airborne dust out of the air and return it safely to the material stream and manufacturing equipment that contains dust at the source and provide solutions that suppress dust after it’s in the air.

Flow Aid

High-performing belt cleaners keep belts clean, eliminating carryback and making conveyor systems safer and more productive. Our belt cleaners that work with all belt sizes and speeds, regardless of industry or type of material. We also offer belt cleaners that work in the most challenging and unique environments, such as on conveyor systems where there’s minimal space around the head pulley.

With our experienced technicians, we’re able to offer an unmatched level of support and service to the facilities we visit. And many of our engineers and technicians have previously worked for mining companies like yours, so we have a unique perspective and advantage when it comes to knowing the issues you face from your viewpoint. We have decades of direct experience, and we know where the process can get bogged down. More importantly, we know how to fix the problems when they arise.

Contact a Martin representative to find out how we can apply our vast mining experience to solve your problems the right way.