DATA

Who are the leading innovators in robotic coal mining?

The mining industry continues to be a hotbed of innovation, with activity driven by safety, productivity and cost control.

Powered by

Robots are designed to increase mine safety by preventing mine accidents that are relatively frequent in underground coal mines. Robotics, integrated with artificial intelligence and the internet of things, can help mining companies develop technologically sound mining infrastructure that can enhance safety and improve accessibility. In the last three years alone, there have been over 48,000 patents filed and granted in the mining industry.

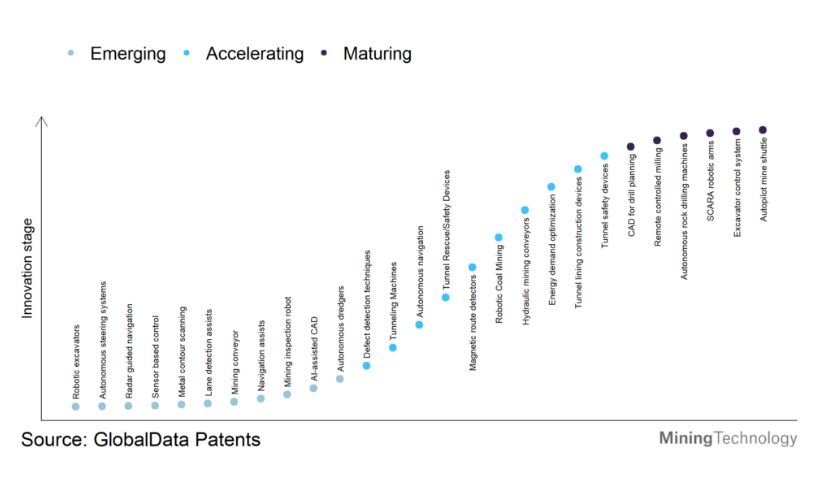

However, not all innovations are equal and nor do they follow a constant upward trend. Instead, their evolution takes the form of an S-shaped curve that reflects their typical lifecycle from early emergence to accelerating adoption, before finally stabilising and reaching maturity.

Identifying where a particular innovation is on this journey, especially those that are in the emerging and accelerating stages, is essential for understanding their current level of adoption and the likely future trajectory and impact they will have.

According to GlobalData’s Technology Foresights, which plots the S-curve for the mining industry using innovation intensity models built on over 350,000 patents, there are 150+ innovation areas that will shape the future of the industry.

Within the emerging innovation stage, defect detection techniques, energy demand optimisation and magnetic route detectors are disruptive technologies that are in the early stages of application and should be tracked closely. Hydraulic mining conveyors, tunnel safety devices and tunnel lining construction devices are some of the accelerating innovation areas, where adoption has been steadily increasing. Among maturing innovation areas are CAD for drill planning and SCARA robotic arms, which are now well established in the industry.

Robotic coal mining refers to fully autonomous mining systems that result in the most productivity gains as software controls one or more mining vehicles allowing operators to take on the role of mining facilitators, troubleshooting errors and monitoring efficiency. In addition, robots are also used to detect hazardous gas as the majority of coal is extracted from underground. Consequently, workers have to enter and work in confined spaces.

In the recent years, the mining industry has increasingly integrated autonomous systems to modernise and advance mining methods and techniques. Furthermore, as global demand for minerals grows, such technologies will allow access to deeper and more difficult-to-mine orebodies. While coal production is being phased out in many countries, it remains the world’s single most important source of energy for generating electricity.

GlobalData’s analysis also uncovers the companies at the forefront of each innovation area and assesses the potential reach and impact of their patenting activity across different applications and geographies. According to GlobalData, there are 10+ companies, spanning technology vendors, established mining companies, and up-and-coming start-ups engaged in the development and application of robotic coal mining.

Leaders in Robotic coal mining include Komatsu and Sandvik AB. Komatsu's autonomous mining systems include remote oversight and operations, automated haulage, high precision cutting, proximity detection, collision avoidance, M2M communication, and auto-bolting.

Komatsu uses the power of data and technology to improve safety in underground coal mines, enhance productivity, and performance. Komatsu introduced the AFC Faceboss RS20s control system in August 2022 to improve operational synergy and safety in longwall coal operations. The control system, which is based on the existing RS20s platform for powered roof supports, leverages a diverse pool of engineering resources and technological know-how to improve armoured face conveyor performance and expand the possibilities of underground coal mining.