COMPANY Insight

With potential staggering costs, mining companies simply cannot afford to neglect the effects their operations have on nature. Andrew Reese, Global Industry Manager for Endress+Hauser, describes what they can do to prevent an ecological disaster

Mining operations not only face the challenge

of optimizing production cost, but also remaining environmentally compliant with rules and laws becoming stricter.

Andrew Reese, Global Industry Manager for Primaries & Metals at Endress+Hauser explains in this interview what a mining operation can do to protect the environment.

Naturally compliant

Scroll down to read the article

Let’s start with a provocative question: Mining can be described as a constant struggle with nature, so is it not controversial to speak of mining and environmental protection in the same sentence?

Of course, a lot of people associate mining with very

negative ecological trends. And to an outsider it may

seem that there are no rules at all. But that is not in the slightest true. What is lacking is a global and harmonized standard. In fact, a lot of recommendations and guidelines

on environmental protection and mining exist. Especially in the European Union.

Could you name one?

The most important one is definitely the EU directive on Integrated Pollution Prevention and Control (IPPC). It outlines not only limits and guidelines but also provides mining operations with reference documents that also list best available techniques and technical information. All of this is available online. But sadly, a lot of mining operations

only make use of these documents after something has happened. Only a few act proactively and are certified according to the standard ISO 14001.

What are the risks involved if a mining operation does not follow certain standards to protect the environment?

Well, that’s the thing, isn’t it? As long as nothing happens, there are no costs. But if there is an environmental accident, the costs be as high as billions of euros. Think of a tailings dam failure for example. Such an accident can affect a huge area of land for a very long time. Not to mention the risk it can have on the local population.

Let’s be a little bit more concrete: What can mining operations do to protect the environment?

They can do many things. For example, they can check and improve their basic processes to minimize chemicals and water consumption, they can look at their water sourcing and they can monitor their effluents of water and gases.

So, water and water monitoring plays a huge part here.

That’s why a sensible environmental protection plan is a must for any mining operation.

But does Endress+Hauser have any experience with water-related applications?

Endress+Hauser has had a strong presence in the water industry since its conception in the 1950s. Water & Wastewater is one of our seven strategic industries just like Primaries & Metals. This means we have colleagues with a vast experience dedicated to various water-related applications.

This includes not only municipal wastewater but also industrial wastewater. We also have a dedicated portfolio for water-related services and instrumentation designed to meet industry requirements.

Why is water essential for mines?

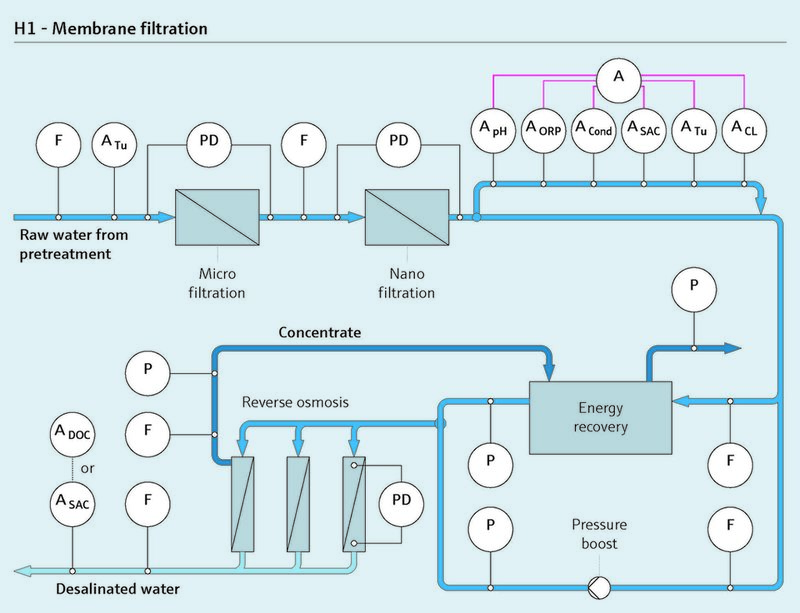

Mines need water not just for their processes but also as drinking water. Don’t forget, a lot of people work and live at a mine. This can be a problem, if the mine is located in an arid area. Some of them even use reverse osmosis to desalinate their water. When it comes to the process water, it has to be of a certain standard depending on the separation process it is used for. Operators therefore have

to monitor the pH value, dissolved oxygen or the metal content. Something we can offer with our analyzer solutions.

You can play a really important role in the mining lifecycle by getting this stuff right early on

What happens with the water after it has been used?

Water used in theses processes has to be treated so it can be safely discharged into various bodies of water. This is one of the most critical aspects when it comes to mining and the environment. And there are pressure groups who keenly monitor the water that is being discharged

from the mines. So operators have to be very careful.

Endress+Hauser offers both stationary and

portable systems with which our customers can monitor their discharges according to the laws and guidelines that apply to them.

Let’s say, you are a mining operator and you are faced with coming up with an environmental protection plan.

What would your first steps be?

First of all, I would get into contact with the local

communities to get them on board. Transparency is key here, as there are a lot of misconceptions about mining.

But of course there are also a lot of benefits. Not just the mined resources like gold or other precious metals but we are also talking about jobs and infrastructure like roads or a water desalination plant. And then as a next step I would

get into contact with companies like Endress+Hauser

that have experiences with monitoring and the specific challenges of my industry to support me with the creation of an environmental protection plan. Finally, I would communicate all this to my local communities to win their support and assure them that the benefits of the mining operation outweigh the risks.

Andrew Reese is an industry leader in process automation, control and instrumentation holding senior management positions at General Electric (GEC) and Siemens before joining Endress+Hauser where he works as the Global Industry Manager for the Primaries&Metals sector. In this role he acts as a senior consultant for process optimization in mines, cement and steel plants of all shapes and sizes. Andrew was born in Liverpool and is both a fan of dark, witty humour and the Everton Football Club.

Contact Information

Website: www.endress.com

Contact Endress+Hauser via their online form

Phone: +41 61 715 7700

Fax: +41 61 715 2888