High-Pressure Acid Leaching Valves

SchuF Valves: Specialists in HPAL severe-service applications

The SchuF Group specialises in dealing with the most severe-service conditions found in the mining and mineral ore processing industry, and produces a broad range of valves for mineral processing operations, including pressure letdown-control, drain, feed, and isolation valves.

- High solids content

- Abrasive materials

- Corrosive chemicals

- A combination of all the above

valves@schuf.ie | tel. +353 21 4837000 | www.schuf.com

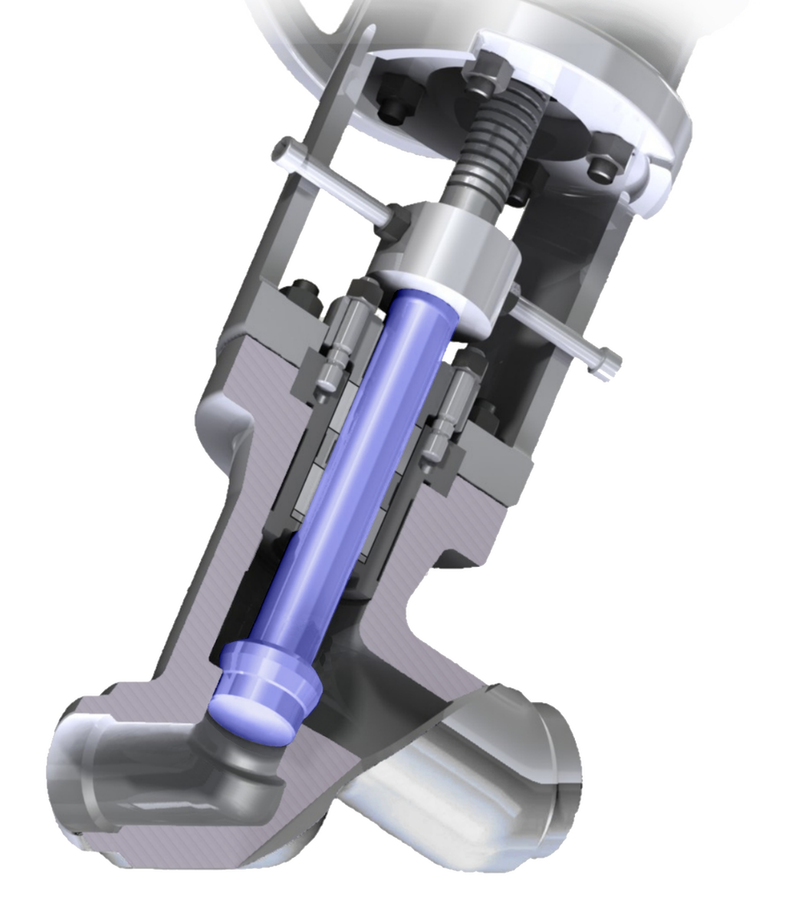

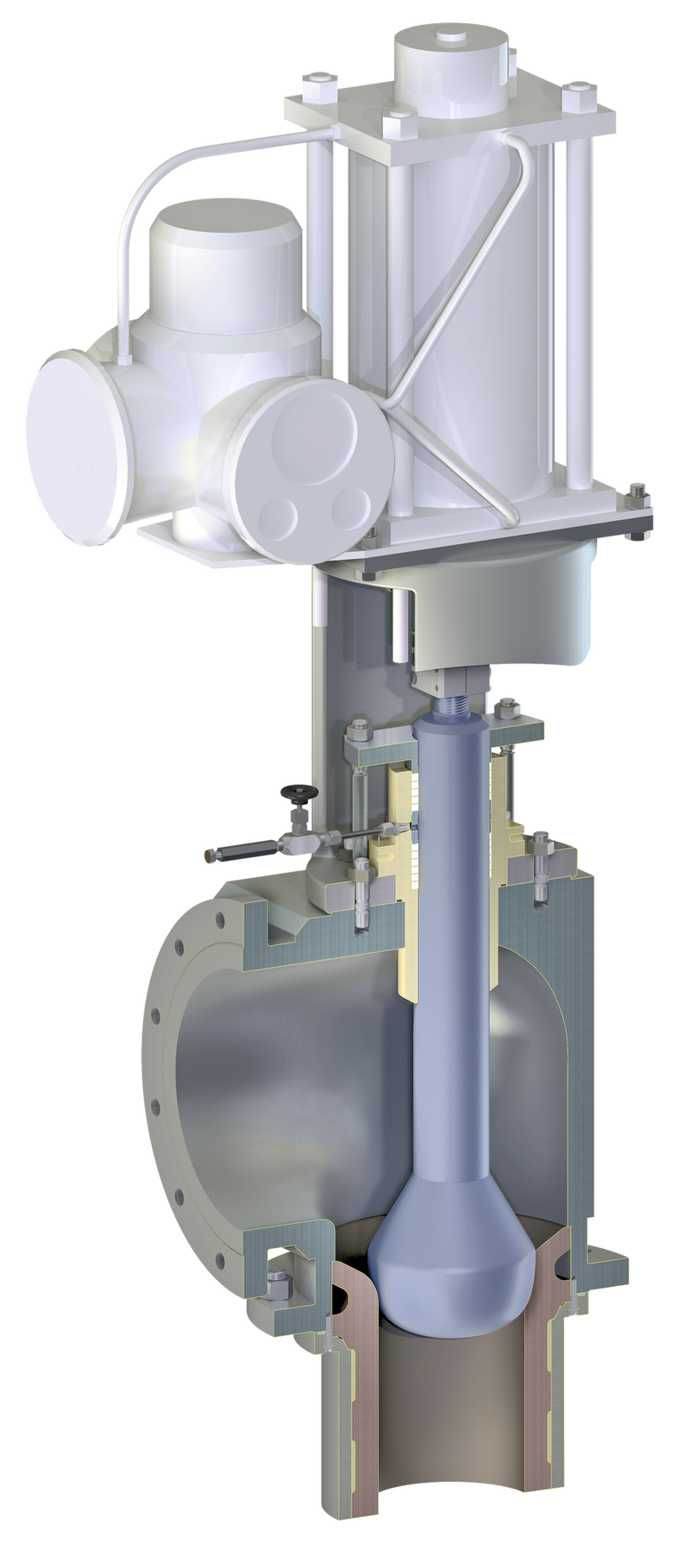

Type 74CS Angle Control Valve

Actuator Choice

SchuF can provide a full range of actuator types- manual, pneumatic, electrical, hydraulic, or gas-over-oil

Cast Yoke

These guarantee a robust and reliable actuator-to-body connection

Full range of seal-to-atmosphere options

All possible packing-ring materials can be provided, as well as further options such as live-Ioaded packing and leak-detection systems

Stem Lubrication

Available on request

Cast Body

Material selection entirely to customer requirements. The sweeping-angle body geometry provides constant media flow acceleration to the seat

Control Disc with Spindle

Providing maximum control performance and exceptional corrosion and erosion resistance utilising ceramic trim

Blast Tube

This will provide seating for the disc along with optimal flow control. Material such as Hexoloy will outperform ceramic and metal superalloys for strength, hardness and corrosion resistance

Seating Sleeve

Designed to perfectly mate with the customer’s mounting/installation point, leaving no dead-space

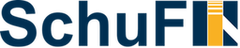

Type 28KS Ram Drain Valve

Optional Mounting Flange

A bespoke pad or mounting flange can be supplied for complete dead-space free installation

Sealing Faces

A selection of hard-faced sealing surfaces are available for high-performance, Iong-Iife service

Ram

Designed to perfectly mate with the seat and vessel- with fully hardened, diamond-polished surface to extend packing life

Body Material

Cast or forged material selection (e.g. Duplex, Hastelloy, Titanium, or other superalloys)

Full range of seal-to-atmosphere options

All possible packing ring materials can be provided, as well as further options such as Iive-Ioaded packing and leak-detection systems

Cast Yoke

These guarantee a robust and reliable actuator-to-body connection

Actuator Choice

SchuF can provide a full range of actuator types- manual (with or without bevel gearbox), pneumatic, electrical, hydraulic

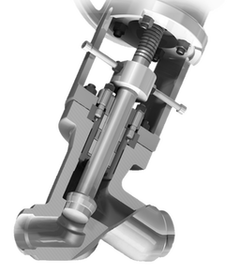

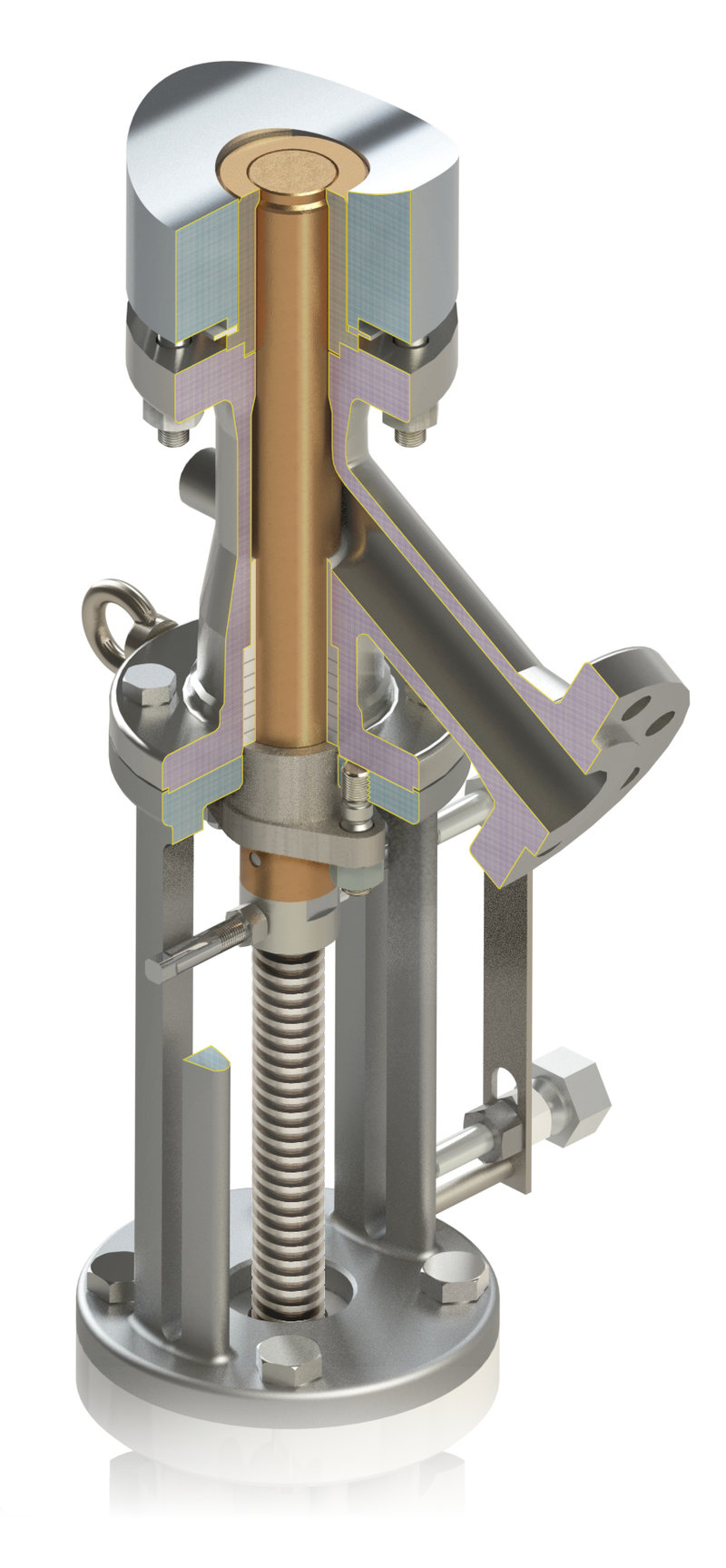

Type 50 Y-Globe Isolation Valve

Actuator Choice

SchuF can provide a full range of actuator types- manual, pneumatic, electrical

Cast Yoke

These guarantee a robust and reliable actuator-to-body connection

Full range of seal-to-atmosphere options

All possible packing ring materials can be provided as well as further options such as live-Ioaded packing, pressure-seal and leak-detection systems

Cast Body

Optimised-flow body design provides a low pressure-drop. Material selection according to customer specification

Ram or One-Piece Disc/Spindle

The Type 50 can be provided with a ram or a disc-with-spindle design (shown here). The disc design can also incorporate dead-space-free back-seat sealing, and disc-grinding is a further available option to clean the valve seating area. Tight shutoff to ASME Class VI or API 598 can be achieved.