COMPANY INSIGHT

Sponsored by AWD Equipment

AWD Group – Your Service Partner

Appreciation of the effect of changing regulations enables mine operators to proactively assess and respond to their relative exposure. A proactive response enables the operator to retain control of change processes in advance of a regulatory direction enforcing the change, the resource demand and the timeframe.

By way of example, Aspect Environmental looks at the requirements of the NSW Mining Amendment (Standard Conditions of Mining Leases – Rehabilitation) Regulation 2020 and how operators can respond and retain process control.

F

ounded in 1998, today AWD has more than two decades of experience and a first-rate reputation for service quality and timely parts delivery by focusing on and understanding our customers’ requirements.

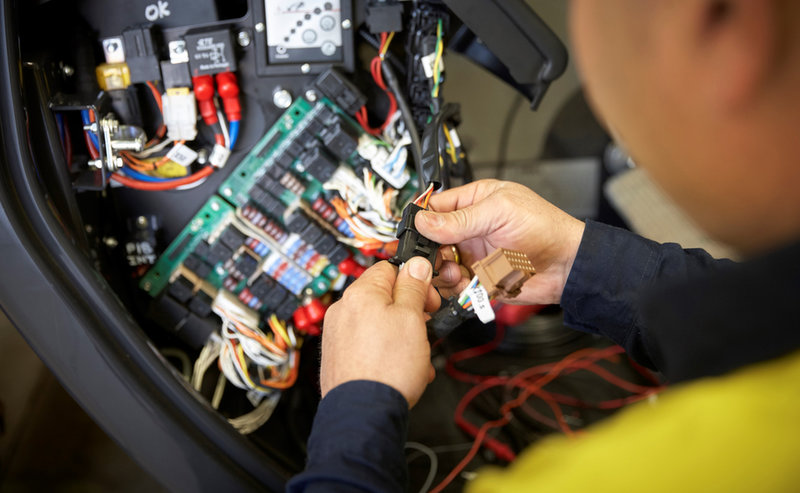

Headquartered in Sydney and with locations in Melbourne, Brisbane and Perth, the AWD team specialises in servicing mobile mining equipment, telehandlers, EWPs, travel towers and forklifts.

With a wealth of industry experience, AWD also specialises in custom engineering our customers’ machines (new or pre-owned) to suit the specialised needs of the Australian Mining industry.

From purpose built underground machines to customised heavy lift site equipment, our team are experts in the needs of the local industry. We can assist in the design and manufacture of purpose-built attachments such as specialised pipe and cylinder grabs to help maximise site equipment efficiency, safety and productivity.

We continuously consult our customer base to obtain direct feedback about our products and services, which allows us to tweak our offering to a level of excellence. Our team builds on client input to create physical solutions for businesses in mining as well as construction and agriculture. Since our team possesses the essential knowledge about the industry, we’re in the best place to offer you practical and professional advice.

AWD specialises in custom engineering our customers’ machines to suit the specialised needs of the Australian Mining industry

Our purpose-built workshop facilities are designed to enable us to efficiently service and maintain all types of equipment with dedicated employees who are fully qualified to offer the correct advice. We also offer major inspections for all makes and models of EWPs such as scissor lifts and boom lifts.

Can’t come to us? Not a problem. We make moving machinery easy with our own fleet of trucks and a network of transport partners who can assist with getting your equipment to wherever it is needed.

A key part to AWD’s servicing strategy is our commitment to mobile service. Our technicians provide on-site equipment service support thanks to our fleet of fully equipped service vehicles across the country.

“Our mobile service fleet works extremely well to reach customers that can’t get to us,” says Perth Service Manager, Paul Thomas.

“We can assist with a wide range of regular maintenance tasks, as well as emergency breakdown response and repair. Our service team can also provide over the phone technical advice on all makes and models of equipment.”

“This means our customers have a readily available resource that would otherwise demand capital investment, staff and workshop space. You can count on us to have the right solution every time, so you can get back on track without delay.”

In addition to our standard mobile service fleet, AWD also has a fully equipped fleet of mobile hydraulic hose and fitting repair vans. Available 24 hours, 7 days a week, the vans are stocked with a large range of hydraulic hoses, industrial hoses and fittings.

From purpose built underground machines to customised heavy lift site equipment, our team are experts in the needs of the local industry.

For operators of heavy machinery and many kinds of capital equipment, a hydraulic hose repair poses a particularly challenging problem. The hydraulic systems may only be a small part of the unit's overall functionality or part of a mission-critical assembly that can't function without robust hydraulic pressure. While some repairs might be possible with help from in-house professionals, in many cases, you may need to seek an outside resource for assistance. At AWD, we provide the gold standard of industry-leading service for operators of hydraulic equipment. When you run into problems, you can rest assured that we have a rapid solution available.

At AWD, we understand the cost of machine down-time caused by not having the part on hand to get equipment back up and running. Therefore, our large, on-site parts inventory is stocked with high-quality parts to ensure your machines can run at their best. We also specialise in genuine OEM parts supplied through our authorised service partners Dieci Australia, Genie, JLG and Bronto Skylift.

The team at AWD is not one to stand still and we are continually exploring ways to offer increased parts support and service offerings.

“We understand the demands, requirements and competitive nature of the market in which we operate, which is why our passion is to consistently exceed our customers’ expectations.”

The AWD Group’s customer service support team is available 24/7, 365 days a year.The AWD Group’s customer service support team is available 24/7, 365 days a year.

Our mobile hydraulic hose and fitting repair van is available 24 hours, 7 days a week.