company INSIGHT

Sponsored by: Endress+Hauser

Every drop counts

Endress+Hauser is a global leader in measurement instrumentation, services and solutions for industrial process engineering. We provide process solutions for flow, level, pressure, analytics, temperature, recording and digital communications, optimizing processes in terms of economic efficiency, safety and environmental impact. Our customers come from various industries, including chemical, food & beverage, life sciences, power & energy, primaries & metal, oil & gas and water & wastewater.

350 liters per hour – that is how much diesel a mining truck consumes on average. No wonder, that fuel is one of the biggest expenses for mining operations. Therefore, intelligent and reliable fuel management can help make operations more cost-effective. But that is not the only advantage customers can expect, when relying on Endress+Hauser’s measurement and automation offering.

24 hours a day, 7 days a week – mining trucks are in almost constant use. Their main task is to transport the rock from the pit or the crusher to the processing. Their loading capacities can be as high as 450 t – add to that their enormous size and weight and it is no surprise that their fuel consumption is higher than that of your average car or truck. Up to 350 liters of diesel are consumed by an average mining truck. Per hour. And of course, most mining operations use several trucks plus other vehicles like bulldozers, haulers and loaders. For mining operators this means they must make sure, that they always have sufficient fuel reserves on site.

Rockwell Application solution overfill-prevention system

Do your homework: the importance of feasibility studies

“You have to keep in mind that most mining operations are in remote areas that are not that easy to reach. This means a mining operation can lose several days of production if they run out of fuel. In a way, you can call it even the lifeblood of the mining industry. Every drop counts”, explains Andrew Reese, Global Industry Manager at Endress+Hauser.

Although the importance of fuel is obvious, it is rarely monitored or controlled in a systematic way. Endress+Hauser can improve this situation with instruments and automations solutions to make fuel management more efficient and safe.

Fuel management starts with the delivery from the supplier. Sometimes there can be disagreements on the delivered amount of fuel. Suppliers use mostly mechanical flowmeters which have an accuracy of 0.5%. This may not seem much, but if you factor in the huge amount of fuel a mine needs, such a discrepancy can make a big difference. Special loading metering skids by Endress+Hauser use Coriolis flowmeters with an accuracy of 0.1%. Plus, their special density calibration can detect if the fuel has been watered down. The overall accuracy of the rig is 0.25%.

IMS Overfill Prevention System Masterfile

Once the fuel is on site, it needs to be stored and managed in a way, that ensures the availability and safety of the operation. The Endress+Hauser inventory management solution give operators the real-live data they need to make the right decisions. This solution consists of system components like PLCs, gateways and telemetry systems as well as accurate, safe and reliable level and temperature measurement instruments.

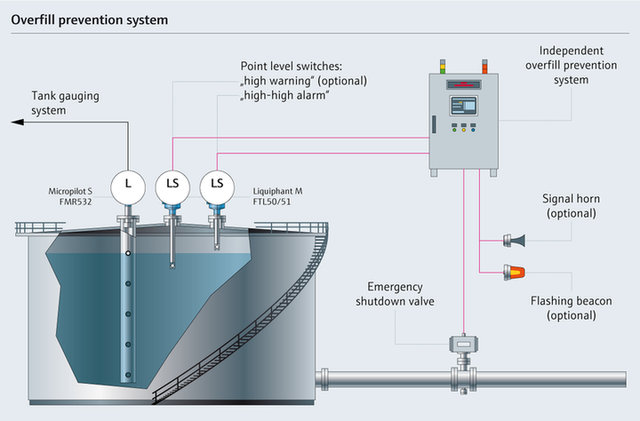

Handling a flammable substance like fuel is always also a safety issue. Handling fuel incorrectly – think of overfilling a tank - can lead to accidents and harm the environment. Endress+Hauser offers a complete overfill prevention solution which is certified by independent, global operating safety experts. It is the best-in-class safety compliant solution, according to IEC 61511. An automated proof test guarantees that the safety instruments system functions perfectly. Proof-testing of 16 tanks takes less than 5 minutes.

“The mining industry is a very competitive industry with commodity prices being in a constant flux. Optimization of operational costs is a must to stay competitive and with fuel being one of the biggest cost factors, fuel management is a no-brainer. Endress+Hauser has decades of experience not only in the mining but also in the oil & gas industry, so our offering was developed with the challenges of our customers in mind”, says Andrew Reese.

Standardized Diesel truck loading custody transfer TAS

More than half of the country’s coal mines are managed by pro-Russian separatist militia. Credit: DmyTo/Shutterstock.

Contact information

Endress+Hauser

Kägenstrasse 2

4153 Reinach

Switzerland

Email: info@endress.com

Tel: +41 61 715 7700

Fax: +41 61 715 2888

Eero Knuutila is Head of Service Development at Helsinki Airport.

Image courtesy: Helsinki Airport