SEW-EURODRIVE is a global designer, developer and manufacturer of mechanical power transmission equipment, systems and motor control electronics, headquartered in Bruchsal, Germany. Its broad spectrum of integrated solutions includes geared motors and gear units, high torque industrial gear units, high-efficiency motors, electronic frequency inverters and servo drive systems, decentralised drive systems, plus complete engineered solutions and after-sales technical support/training.

The Australian division of SEW-EURODRIVE is headquartered in Melbourne and is supported by a network of offices in Sydney, Brisbane, Mackay, Townsville, Adelaide and Perth. A comprehensive production, service and technical support centre is located in Melbourne, and is complemented by production, service and assembly facilities in all mainland states.

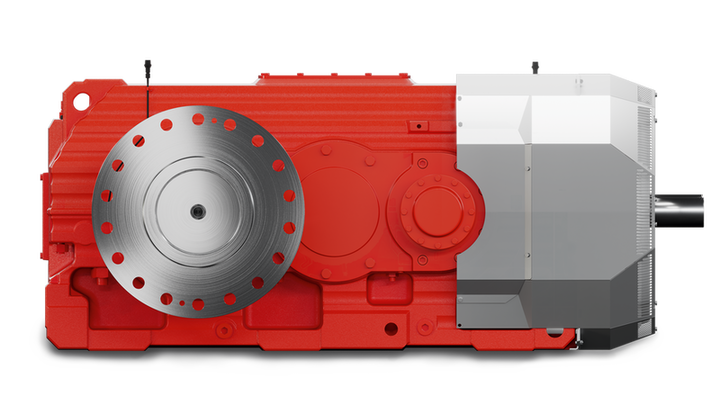

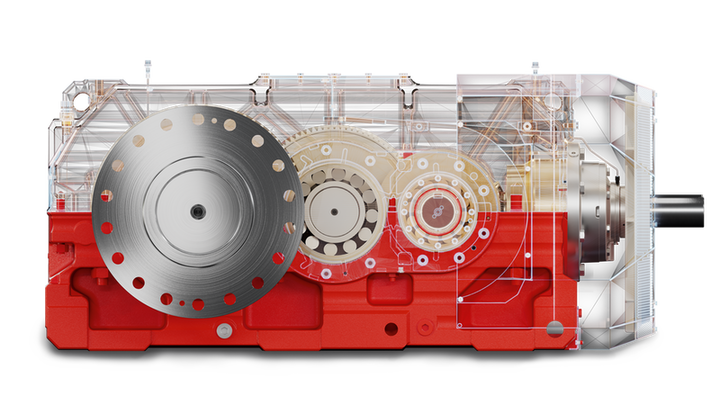

SEW-EURODRIVE introduces the new Generation X.e industrial gear units

Durability, finely graduated sizes, and an invertible housing are the characteristics of our tried and tested X-series industrial gear units.

The new Generation X.e is based on these features and impresses with its added efficiency, experience, and excellence: Because these industrial gear units can be adapted individually and precisely to the respective requirements of your particular application, both in terms of operation and the surroundings.

Gear unit design

Stages

Gear ratio i

Nominal torque MN2 kNm

Helical gear unit

X.F.180e – X.F.250e

2 to 4 stages

6.3 – 400

58 – 175

Bevel-helical gear unit

X.K.180e – X.K.250e

2 to 4 stages

6.3 – 400

58 – 175

SEW-EURODRIVE Pty Ltd

27 Beverage Drive

Tullamarine, VIC 3043

Tel. +61 3 9933 1000

Fax +61 3 9933 1003

sales.vic@sew-eurodrive.com.au

1

2

3

4

5

6

The result is:

Highest possible efficiency

Greater safety

Longer service life, even in harsh conditions

Contactless sealing systems

Contactless sealing systems are not affected by wear at the input and output shaft.

Loss of oil is a thing of the past; and the operational safety is also increased.

Your benefit:

- Significantly longer maintenance intervals for your drive system

X

Thermally improved oil level

We are aware of the fine line between reducing the oil limit and obtaining an optimal heat dissipation. This knowledge enabled us to optimally reduce the oil bath temperature. The result: Increased operational safety, saving of resources, prolonged oil change intervals.

Your benefits:

- Savings of up to 29% of oil volume

- Increased oil service life by up to 110%

- Reduced churning losses by up to 87.5%

- Reduced oil bath temperature by up to 8%

- Increased thermal limit rating by up to 32%

X

Optimized bearing preload

Order-specific settings – always the right bearing preload. This reduces the formation of heat spots. The low compression significantly increases the bearing service life.

Your benefits:

- Increased bearing service life of the gear unit by up to 220%

- Increased thermal limit rating by up to 24%

- Reduction of the oil bath temperature by up to 4%

X

Optimized gearing topology

The optimized tooth flank topology is not very prone to displacements.

Meshing interference can be better tolerated. This helps to avoid downtimes

and increases system availability.

Your benefits:

- Basis for optimized bearing preload

- Higher operational safety of the drive when external forces effect the shafts

- A new calculation in combination with the optimized tooth flank topology allow for increased static overhung loads by up to 41% in case of unfavorable application angles

- Lower gear unit noise due to optimized tooth meshing

X

Improved bevel pinion housing

The improved bevel pinion housing enables an optimized oil flow. This is the basis for a higher thermal rating and results in a higher operational safety. Higher powers can be transmitted without the risk of unexpected machine downtimes.

Your benefits:

- Basis to obtain a 30% reduction in system power loss

- Increased operational reliability and improved cold start behavior

- Increased overall limit rating by up to 153%

X

Universal fan guard

The concept of our universal fan guard allows to arrange various fan sizes (boost, balanced, silent) and fan types under one cover. Not only does this concept facilitate fixed installation dimensions in your system, but it also allows for an optimal cooling while given sound pressure limits are adhered to.

Your benefits:

- Reduction of the oil bath temperature by up to 36%

- Increased thermal limit rating as compared to the current axial fan by up to 54%

- Lowered sound pressure level as compared to the current axial fan by up to 7 dB(A)

X

FIND OUT MORE