Ultrasonic Cleaning Machines For All Industries & Applications

Cleensonic is expanding its range of uniquely designed industrial ultrasonic cleaning equipment. The range now includes standard units suitable for cleaning items as small as electronic PCBs right up to workpieces as large as V18 & V20 diesel engines and automotive gearboxes..

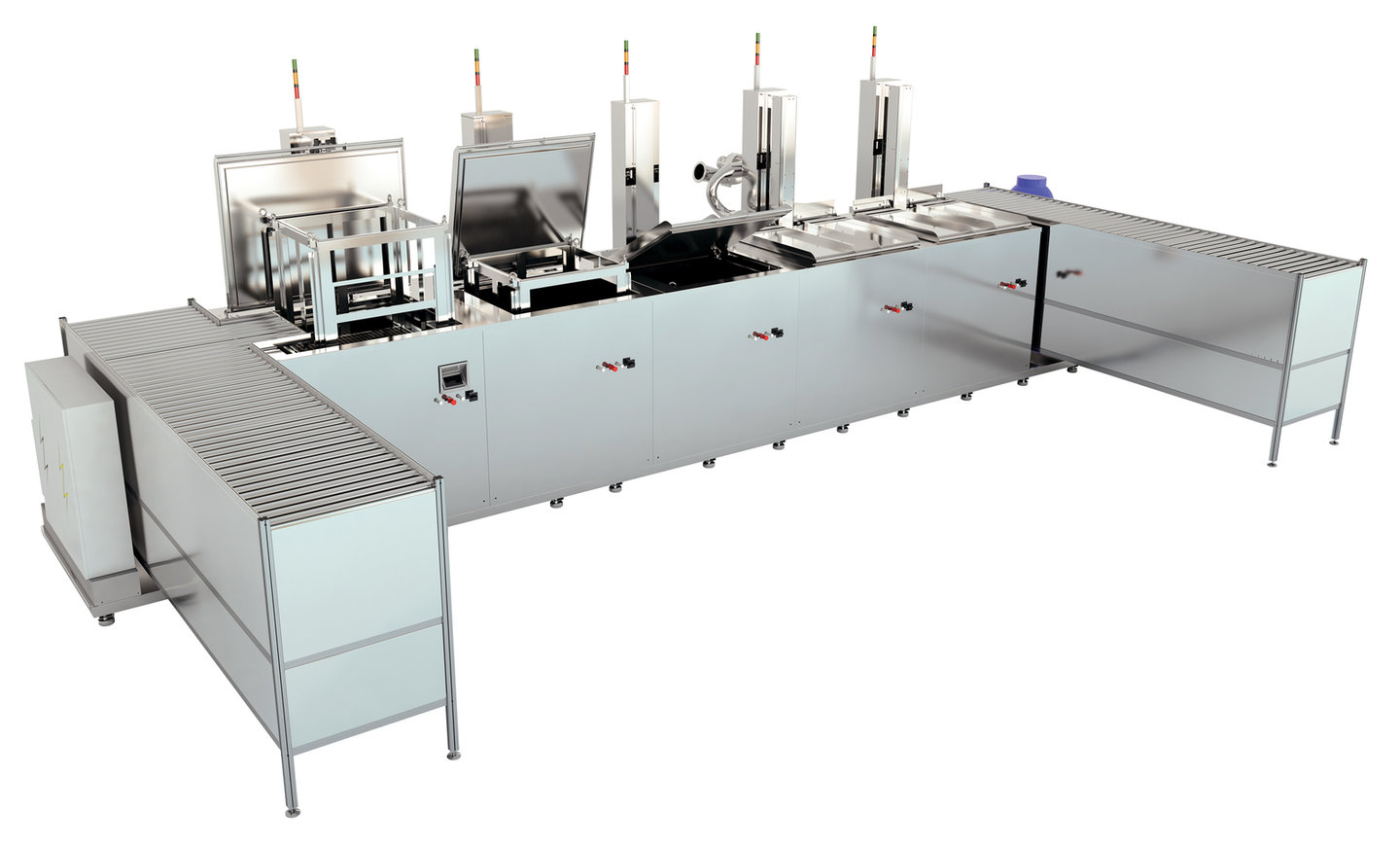

Ultrasonic Multistage systems are ideal for customers searching for repetitive cleaning of parts during their processes.

About Cleensonic

Cleensonic has 20 years of experience across Ultrasonic cleaning technologies and understands the importance of tailored designed cleaning equipment for various organisations and facilities.

Ultrasonic cleaners are unsurpassed when it comes to removing contaminants from virtually any hard surface that can be safely immersed in a cleaning solution.

We can help you find the right solution.

Why Ultrasonic?

In a manufacturing environment, ultrasonic cleaning systems can be integrated into the production process and used to remove residues from manufacturing processes and manufacturing assets such as moulds and tools can be cleaned after use without fear of damage.

In general maintenance work, ultrasonic cleaning systems are perfect for removing dust, dirt, grime, grease, carbon, oils and other contaminants from all manner of assemblies – either prior to maintenance or simply to improve performance of components such as filters, radiators and heat exchangers.

A key advantage of ultrasonics over other cleaning methods is its ability to clean hidden cavities (effectively in every nook and cranny). No matter how complex the structure of the workpiece, once it is immersed in the ultrasonic bath, the vapour-filled bubbles created by the ultrasonic process permeate through the cleaning fluid, bursting and releasing the energy that performs the cleaning process.

In addition to the standard range, the company is also actively involved in designing and manufacturing custom systems to suit all manner of ultrasonic cleaning challenges."

Benefits

Cleensonic also offers a wide range of technical solutions to build up a custom complete system for each industry cleaning requirements. Each line is adjusted and configured with the desired wash, rinse and drying stages according to customer needs.

Flexible, reliable and robust systems starting from 100litre tank capacity up to 15,000litre for each stage.

Multistage lay-out allows easy parts handling by using overhead cranes, custom automated manipulation systems or robotized systems. Customised baskets can be used to ensure perfect integration at customer manufacturing or maintenance processes.

Ultrasonic Multistage systems are ideal for customers searching for repetitive cleaning of parts during their processes

Clean Faster

As there is no manual cleaning required, Ultrasonic can clean hard to reach internal cavities with ease and minimises the need for disassembly of components being cleaned.

Clean Consistently

The results don’t depend on the operator’s skill…anywhere the liquid touches is evenly cleaned at a microscopic level.

Cut Costs

Put the part in the tank, turn the machine on and walk away. There is no need for continuous

operator activity.

Clean Safely

Ultrasonic is safe for workers due to hands-off cleaning and reduced contact with harmful or

harsh chemicals and removal of harmful solvent vapours.

Product Range

Cleensonic offer a large range of Standard industrial standard ultrasonic cleaning machine ranging in size from 15 - 15,000litres

There is the CREST Powersonic Benchtop machines: 2.8 - 26 litres

There is the CS Series Industrial BenchTop Machines: 15 - 170litres

There is the ACM Series of Agitation platform plus ultrasonic machines: - 100-7,500 litres

There is the ICM Series with just ultrasonic cleaning : - 100 - 15,000litres

CREST Benchtops

CS-Series Benchtops

ULTRATECNO Industrial

Custom Ultrasonic